1.Before and during the war1930-

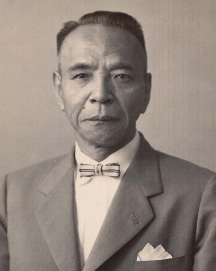

Benzo Nakakita, the first president, founded Nakakita Seisakusho

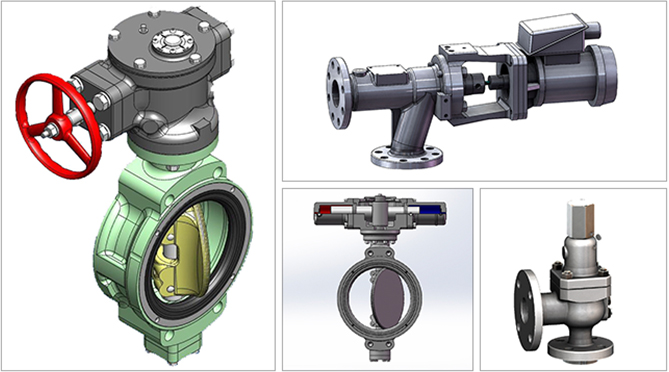

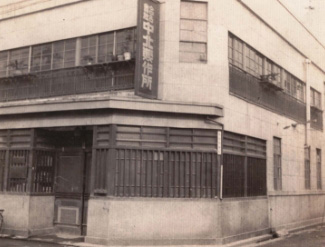

In May 1930, Nakakita Seisakusho was established in Matsugae-cho, Kita-ku, Osaka City as a house and factory. It was a small private organization with only a few employees. The first products were automatic control valves such as automatic float switches and pressure switches, which marked the beginning of Nakakita's history of automation.

Benzo went on to develop new products one after another, acquiring dozens of patents and utility models. The reputation of "B-N" products, named after Benzo's initials, grows and the foundation of Nakakita Seisakusho is solidified.

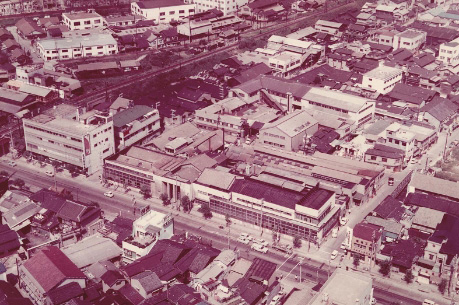

New factory built in Gamo-machi, Joto-ku, Osaka.

In May 1937, the factory was moved to Imai-cho, Kita-ku, Osaka City, and the company was incorporated. 1939, with the steady expansion of business, the existing factory became too small and a new building was planned. In June, a new company building and a new factory in Gamo-cho, Joto-ku, Osaka were completed.

World War II

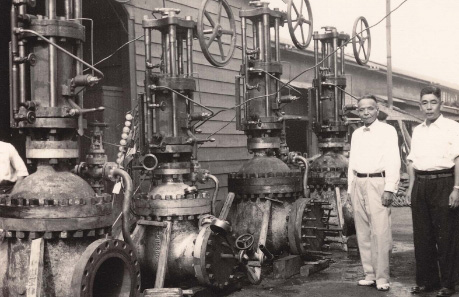

In 1939, World War II broke out. Nakakita Manufacturing was also included in the wartime regime and designated as a naval controlled factory in 1942. The company was ordered to manufacture valves for transport ships, mainly cast iron and steel stop valves, and at its peak, nearly 1,000 employees were engaged in production.