Nakakita Manufacturing

~Creating Fluid Control Equipment to Support Global Infrastrucure~

~Creating Fluid Control Equipment to Support Global Infrastrucure~

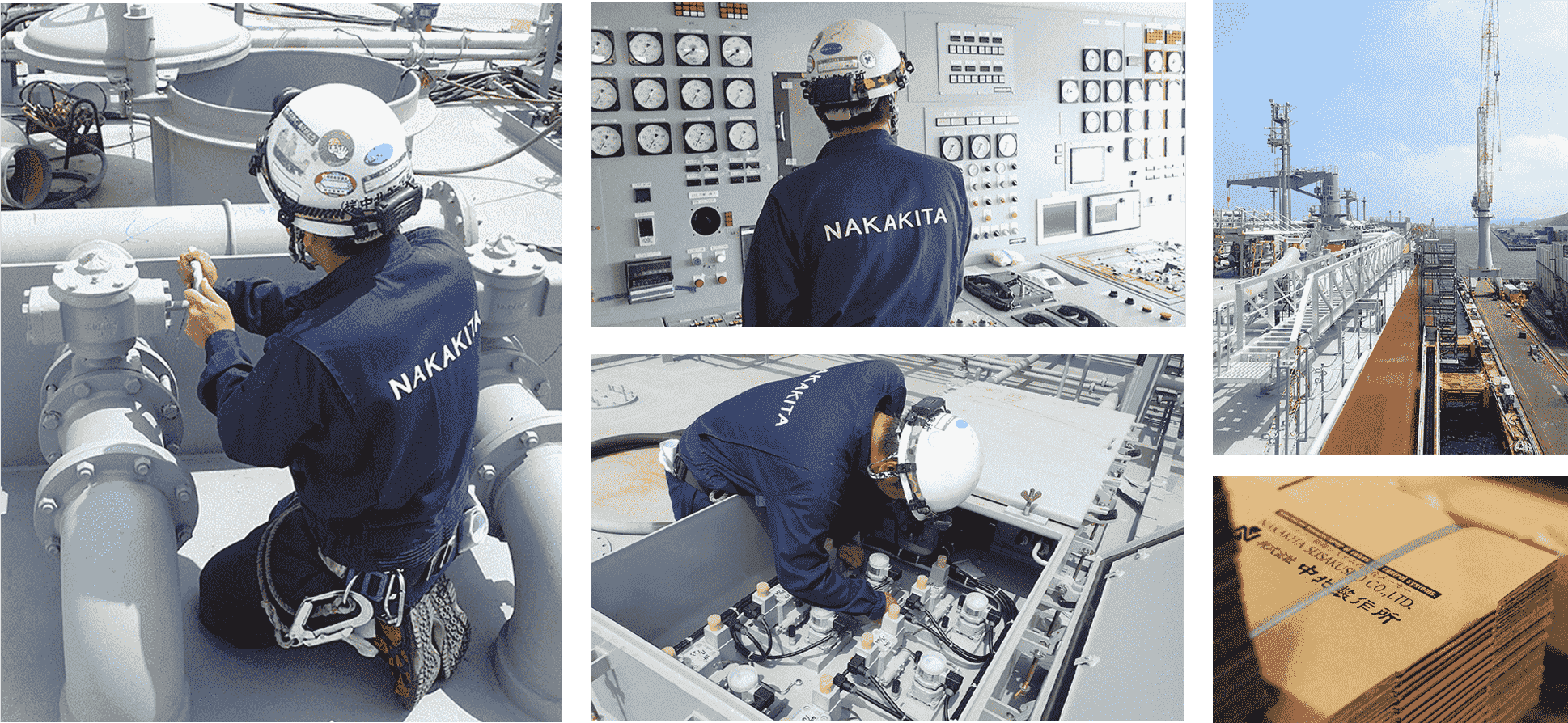

For roughly 90 years since the company's founding, Nakakita has been deeply interwined with various industries, including the shipping industry.

Our Sales staff apply this established network to fulfill customers’ requirements.

Paying careful attention to details by our Sales personnel, is another aspect of Nakakita’s greatest strengths.

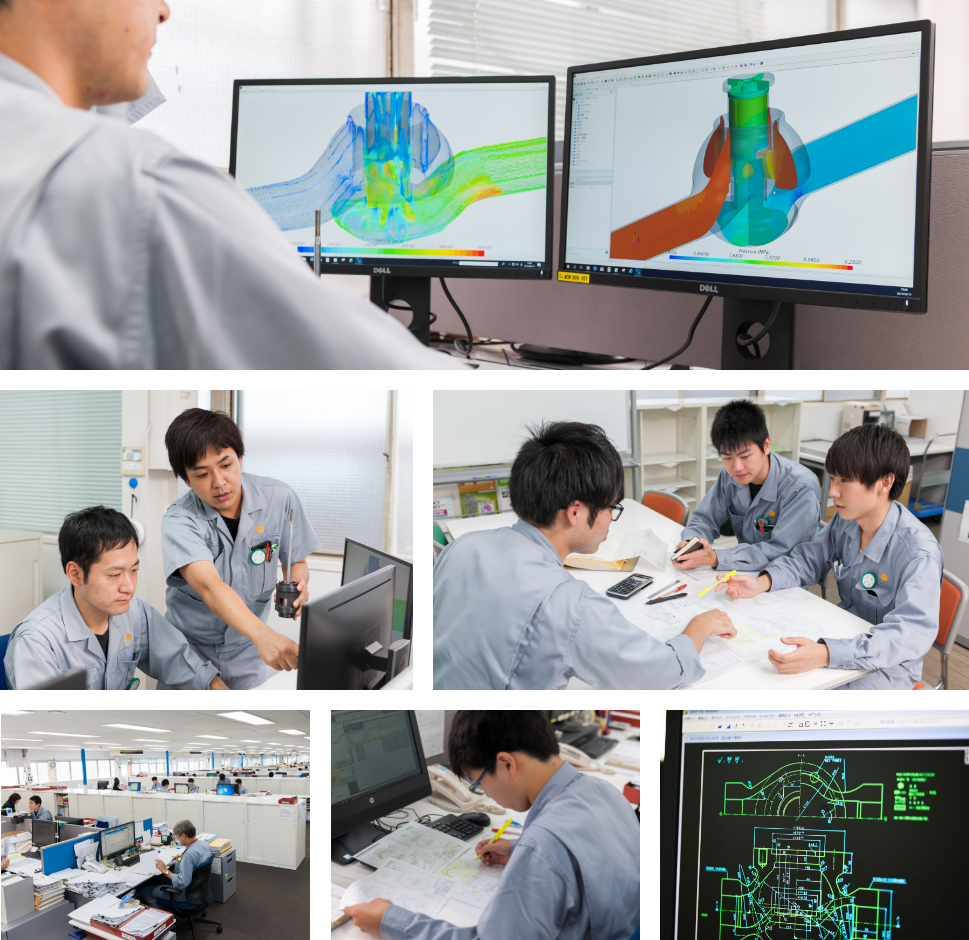

Each of Nakakita’s products is unique.

Engineers design each product based on specifications provided by the Sales staff.

This is the cornerstone of all of our manufacturing efforts.

Fluid control equipments include valves, indicators, and control panels, while with each equipment type requiring diverse manufacturing processes.

Nakakita utilizes state of-the-art processing equipment to meet complex high variety and small quantity manufacturing needs, and we actively challenge our employees in acquiring various skills through testing to further develop our human resources.

Assembling a wide variety of small-lot products—each of different shapes—can be extremely difficult.

As such, we are constantly looking for ways to improve assembly efficiency.

As a result, the outcome of above eventually appears in form of our finished products.

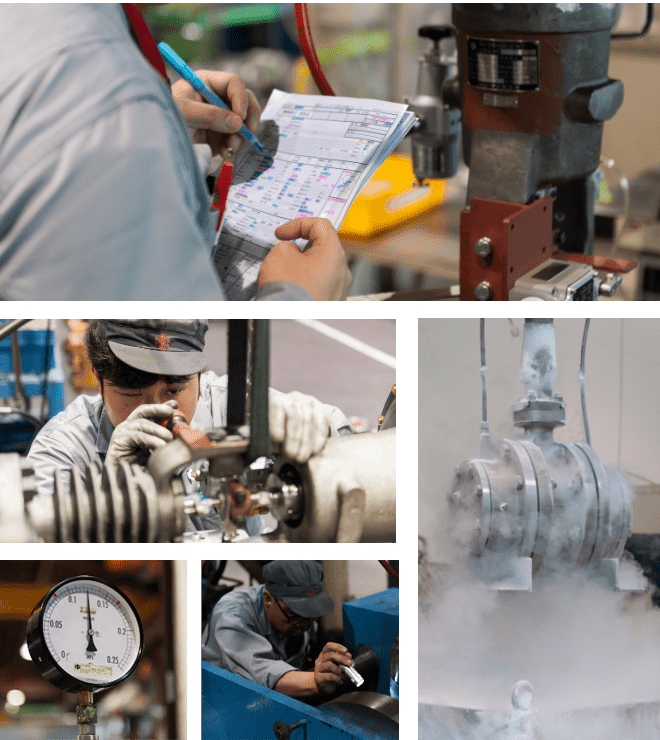

At Nakakita, our motto is “Incorporating Quality into Each Process,” therefore the inspection process by itself, is the final step to ensure superb manufacturing quality.

Our Inspections involve state-of-the-art equipment and facilities developed in-house for their exclusive use with our products.

“Manufacturing” doesn’t end with finished product’s shipment.

We are also dedicated to providing After-sales Services for the shipped products until the end of their service life.

We also value feedback from customers as a means of ensuring the continued advancements of manufacturing at Nakakita.